|

Sunrise Metal Technology Co., Ltd

|

| Price: | 2.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Aluminum Die Casting-Precision mounting bracket for medical part

Factory Capabilities

Material | Aluminum ADC12(Or A380/ADC10 upon requests) |

Process | Die Casting Raw Material → Trimming → Deburring →CNC machining → chromating →powder coating → package → Shipping |

Equipment of Casting | 1.12 sets Die Casting machine(From160T to 1600T) 2. 41 sets advanced CNC machining centers (3axis,4axis, 5 axis and 7 axis CNC machine center) 3. 2 sets CNC Lathes, 2sets drilling machines, etc. |

Good Inspection Instruments | X-ray Detector, CMM, Spectrum Meter, Imaging Measurement Instrument, etc. |

Precision machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

Surface Treatment | powder coating, polishing, sand blasting, heat treatment, painting, anodizing, electroplating, Chrome plating,etc |

Application | Medical Parts, Ultrasound system, Ultrasound devices, Diagnosis Equipment, Hospital machines, Medical devices, Auto parts, marine & ship equipment, Telecommunication, Textile Industry, etc |

Product Pictures

CNC machining aluminum parts aluminum die casting for Instruments

Sunrise Metal provide the following services to customers:

1. Mechanical Engineering service, we have rich experience mechanical engineering team , we help customer to do the mechanical design for product per customer's function and appearance requirement, do the DFM (Design For Manufacturing) for customer's products, tooling design , production design, etc.

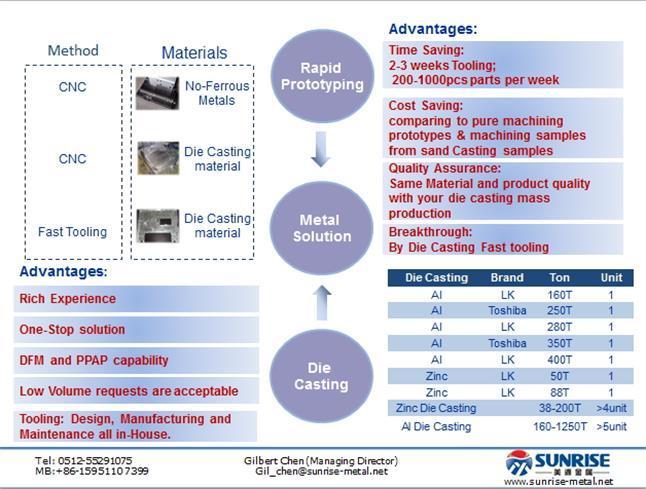

2. Rapid Prototyping Service, we provide good service on prototyping with our rich experience team and our advanced machines for prototyping. we target on over 10 sets metal prototype request. We have three ways to make prototype.

① Pure Machining from steel , magnesium , aluminum , zinc, etc , .

② We cast die casting material block such as A380, A413 ,etc with minimum porosity and then machine the prototypes from die casting material. The porosity are rare and acceptable level .

③ We make fast die casting mold ( Half of Normal tooling lead time ) and then cast the prototypes .

3. Die casting In House Service , we target on high mix , small - medium volume projects. With our rich experience on die-casting , high precision die-casting machine , tooling shop in house & well management , we can provide one stop solution for die-casting components.

4. Supply Management Service, our team members have good English capability , rich supply management experience , advanced QC equipment & QC measuring Skills , etc , we help customer to manage their supply in China . Hope we can have chance to work with you.

Our Advantages

1. Strong R&D capability and rich engineering experience enable us:

a. Design Mechanical parts.

b. Design for Manufacturing

c. Cost saving suggestions.

d. PPAP capability

2. One-stop Solution

Integrate Rapid Prototyping, tooling, Die casting, machining,

assembling in house and surface treatments, together with

various value-added services

3. Fast delivery.

a. Rapid Prototyping: 1-2 weeks for Volume less than 200pcs.

b. Rapid tooling: 2-4 weeks for production tooling, etc.

c. Rapid Production: With Rapid tooling and quick production

arrangement, we can provide quick production delivery.

4. Well trained work team

Honest, easy-going, hard-working and able to work under pressure; Well-trained invocational ethic, good mentality and high work efficiency

Fast Mold Manufacturing Business Unit

Sunrise build up the Fast Mold Manufacturing Business Unit. Our fast mold team dedicate to fast mold. We quick react on tooling design, optimize every processes tooling manufacturing, 24 hour's work, utilize our in-house advanced tooling equipments and excellent tooling supply base in our area,design and manufacture tooling innovative ways. We now can shorten tooling manufacturing time by 50% for hard production tooling and can shorten to 1/3 normal tooling lead time for prototyping tooling.

Our fast mold manufacturing has already help our customer such as Marquart, Hengst, Anologic,etc to save more than 50% project develop time for their urgent project and speed up their project time to market.

Working Method

1.Rapid Prototyping:

Customer will send the primer drawings to Sunrise to make small quantity prototypings to check whether it's suitable for assemble and the function test. Normally customer need the rapid prototyping urgently,so usually we can send the samples to customer within 7 days.

2.DFM:design for manufacture

Before start to make the die casting tooling, we will carefully check the drawing, and per our engineers more than 10 years strong R&D capability and rich engineering experience for aluminum die casting to analyze the drawing, and will submit the perfect DFM,we also can discuss with our customer together to solve key point that don't affect the part function and cost saving suggestions.

3.Start to Make Die Casting Tooling

When get the customer's agreements for our DFM,such as confirm the moving die and fix die,ejector pin location,slide,parting line,machining location etc.,then we will start to make the die casting tooling,and will send the die casting tooling schedule to customer,and every week our engineer will update the schedule,then send to customer and inform that we are on the schedule. If any question will delay the schedule, we will send the current conditions to customer in advance.

4.Trial Run the die casting Tooling

When finish the die casting tooling, we will arrange to trial run it, normally the first time we will trial run 10pcs of die casting raw material,then per the processes to follow each process,then send the samples to customer to approve it. Normally the lead time is around 2 weeks.

If the first trial run result wasn't good, we can modify the tooling in house, we have grinding,Milling,CNC,EDM machine in house, so we can quick responds to modify,then trial run again.

And if customer would like to ECN, it's also no problem for us,we can modify the ECN in house too.

5.FAI report and PPAP files

When we send out the samples, we will submit the FAI report and PPAP files if customer need it.

6.Mass production

When we get customer approval, we can start to mass production immediately.

General view of factory