|

Sunrise Metal Technology Co., Ltd

|

| Price: | 2.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Die Casting Aluminum alloy from Raw Material to perfect products

Specification of Diecast parts

We can provide various of die casting parts of all industry fields upon your requests and drawings,like Telecommunication parts/telecom parts as below,

Critical parts are required more and more to be tested during the manufacturing process by more efficient and accuracy non destructive evaluation methods,such as high standard ultrasound device parts we made foe our customer.

Factory Capabilities

Material | 1. Aluminum (A380,ADC10,ADC12), Magnesium (AZ91D,AZ30), Zinc (Zamak3# and Zama 5#) 2. No-Ferrous Metals: Aluminum 6061-T6 , 6063-T6, Copper, Brass and Titanium etc. 3. Stainless Steel, etc. |

Process | Die Casting Raw Material → Trimming → Deburring →CNC machining → E-coating→ package → Shipping,etc. |

Equipment of Casting | 1.12 sets Die Casting machine(From160T to 1600T) 2. 41 sets advanced CNC machining centers (3axis,4axis, 5 axis and 7 axis CNC machine center) 3. 2 sets CNC Lathes, 2sets drilling machines, etc. |

Good Inspection Instruments | X-ray Detector, CMM, Spectrum Meter, Imaging Measurement Instrument, etc. |

Precision machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading etc. |

Surface Treatment | powder coating, polishing, sand blasting, heat treatment, painting, anodizing, electroplating, Chrome plating,E-coating. |

Application | Auto parts, Medical Parts, Ultrasound system, Ultrasound devices, Diagnosis Equipment, Hospital machines, Medical devices, marine & ship equipment, Telecommunication, Textile Industry, etc |

| Products | All kinds of aluminum casting: include automotive parts, railroad parts,medical parts, marine parts, lighting parts, pump body, valve parts,architectural parts and furniture parts ,etc. |

Working Method

Rapid Prototyping:

Customer will send the primer drawings to Sunrise to make small quantity prototypings to check whether it's suitable for assemble and the function test. Normally customer need the rapid prototyping urgently,so usually we can send the samples to customer within 7 days.

DFM:design for manufacture

Before start to make the die casting tooling, we will carefully check the drawing, and per our engineers more than 10 years strong R&D capability and rich engineering experience for aluminum die casting to analyze the drawing, and will submit the perfect DFM,we also can discuss with our customer together to solve key point that don't affect the part function and cost saving suggestions.

Start to Make Die Casting Tooling

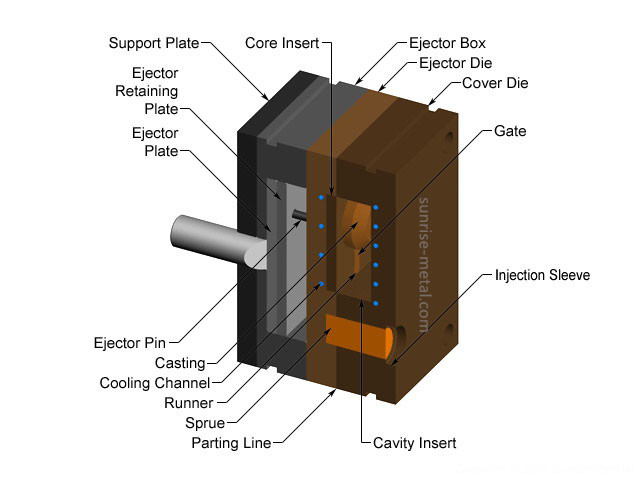

When get the customer's agreements for our DFM,such as confirm the moving die and fix die,ejector pin location,slide,parting line,machining location etc.,then we will start to make the die casting tooling,and will send the die casting tooling schedule to customer,and every week our engineer will update the schedule,then send to customer and inform that we are on the schedule. If any question will delay the schedule, we will send the current conditions to customer in advance.

Trial Run the die casting Tooling

When finish the die casting tooling, we will arrange to trial run it, normally the first time we will trial run 10pcs of die casting raw material,then per the processes to follow each process,then send the samples to customer to approve it. Normally the lead time is around 2 weeks.

If the first trial run result wasn't good, we can modify the tooling in house, we have grinding,Milling,CNC,EDM machine in house, so we can quick responds to modify,then trial run again.

And if customer would like to ECN, it's also no problem for us,we can modify the ECN in house too.

FAI report and PPAP files

When we send out the samples, we will submit the FAI report and PPAP files if customer need it.

Mass production

When we get customer approval, we can start to mass production immediately.

Company Profile

1. Brief Information.

With more than 10 years of experience, our 3 facilities are dedicated to

offering customer aluminum complete solutions including:

a. Prototyping

b. Die Casting Production

c. Machining from solid , extrusion, forging ,etc

2. We offer One-stop Solution .

Integrate Rapid Prototyping, Tooling, Die casting, Machining, Sand

blasting, Tumbling, Cleaning etc. all in house and out-sourcing other

surface Treatments.

3. Our Core Values:

High Quality , Fast Production, Fast Response , Friendly service

4. Market Target:

High Mix , Low to Medium Volume Projects

Our Advantages

1. Strong R&D capability and rich engineering experience enable us,

a. Design Mechanical parts.

b. Design for Manufacturing

c. Cost saving suggestions.

d. PPAP capability

2. One-stop Solution

Integrate Rapid Prototyping, tooling, Die casting, machining,

assembling in house and surface treatments, together with

various value-added services

3. Fast delivery

a. Rapid Prototyping: 1-2 weeks for Volume less than 200pcs.

b. Rapid tooling: 2-4 weeks for production tooling, etc.

c. Rapid Production: With Rapid tooling and quick production

arrangement, we can provide quick production delivery.

Die casting tooling/Ejector pins

Tooling: Dies and Molds for Die Casting

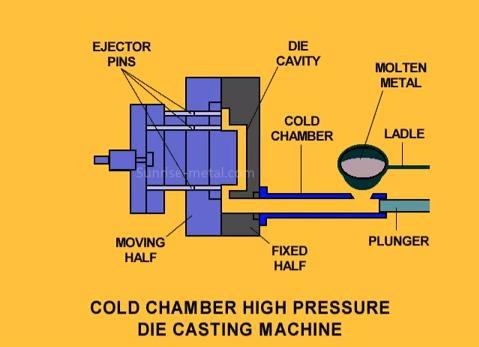

Die cast tooling called insert die, die casting dies, or die casting molds, comes in one part each cycle). Sunrise Metal only uses cold chamber die casting machine tooling dimany styles, sizes, and values. Die cast tooling comes in single cavities (one part each cycle) or multiple cavities (more than es or molds for aluminum die cast parts.

Die cast tooling comes in various forms:

1. Die Cast Tooling Inserts

2. Prototype Die Cast Tooling Inserts

3. Unit Die Tooling

4. Complete Class "A" Die Cast Die or Mold Tooling

5. Die Cast Family Mold Tooling

6. Trim Dies for Die Cast Parts

Our In-House Die Cast Tooling Capabiities include:

Die casting dies.

Die casting molds.

Die casting inserts.

Die cast tooling modifications.

Die cast tooling repairs.

Diecast tooling and trim die manufacture.